Title: Introduction to SFC Programming in Industrial Automation

In the realm of industrial automation, Sequential Function Chart (SFC) programming stands out as a powerful method for designing and implementing control systems. This presentation provides a comprehensive overview of SFC programming, its principles, applications, advantages, and best practices.

Table of Contents:

1. Understanding SFC Programming

2. Key Components of SFC

3. Advantages of SFC Programming

4. Applications of SFC

5. Best Practices in SFC Programming

6. Conclusion

1. Understanding SFC Programming:

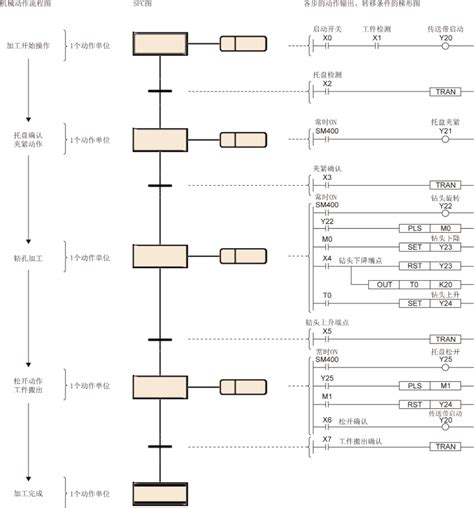

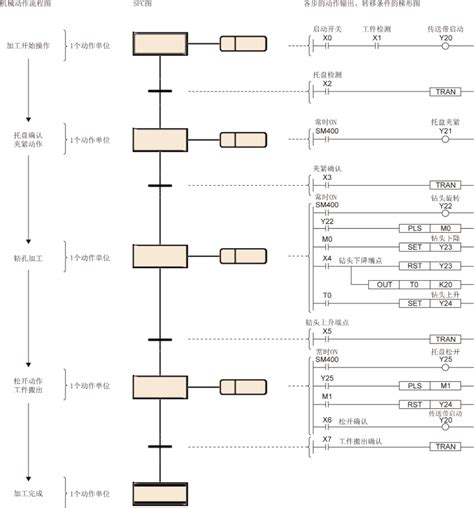

Sequential Function Chart (SFC) is a graphical programming language used in industrial automation to represent the sequential control logic of a system. It provides a structured and visual approach to designing complex control systems, making it easier to understand, debug, and maintain.

2. Key Components of SFC:

Steps:

Represent individual actions or operations within the control system.

Transitions:

Define the conditions for transitioning between steps.

States:

Group of steps that execute sequentially until a transition condition is met.

Actions:

Tasks performed within each step, such as activating outputs or performing calculations.

Conditions:

Boolean expressions that determine when transitions occur.

3. Advantages of SFC Programming:

Modularity:

SFC allows for the modular design of control systems, making it easier to manage and reuse code.

Visualization:

The graphical nature of SFC makes it easier to understand the control logic, facilitating troubleshooting and maintenance.

Flexibility:

SFC supports both sequential and parallel execution of tasks, allowing for complex control strategies.

Safety:

SFC facilitates the implementation of safety functions by providing clear separation between different control states.

4. Applications of SFC:

Manufacturing:

SFC is commonly used in manufacturing processes for controlling machinery, assembly lines, and robotic systems.

Energy Management:

SFC can be applied in energy management systems to optimize resource usage and increase efficiency.

Building Automation:

SFC is used in building automation systems for controlling HVAC, lighting, and security systems.

Transportation:

SFC finds applications in transportation systems for controlling traffic lights, railway signaling, and automated guided vehicles (AGVs).

5. Best Practices in SFC Programming:

Use Modular Design:

Break down the control logic into smaller, reusable modules for easier maintenance and scalability.

Document Thoroughly:

Provide comprehensive documentation for the SFC program, including descriptions of steps, transitions, and state diagrams.

Follow Naming Conventions:

Use consistent naming conventions for steps, transitions, and variables to improve readability.

Test Rigorously:

Conduct thorough testing of the SFC program in simulation environments and on real hardware to ensure reliability and safety.

Implement Error Handling:

Include error handling mechanisms to detect and respond to abnormal conditions, ensuring system robustness.

6. Conclusion:

In conclusion, Sequential Function Chart (SFC) programming offers a powerful approach to designing control systems in industrial automation. By providing a structured and visual representation of control logic, SFC enhances modularity, visualization, flexibility, and safety in control system design. By following best practices and leveraging the advantages of SFC, engineers can develop robust and efficient control systems for a wide range of applications.

References:

[Example Ref 1]()

[Example Ref 2]()

[Example Ref 3]()